Every inkjet system, no matter how advanced, depends on one deceptively small component: the printhead. It is where digital design becomes physical reality, as carefully engineered waveforms and fluid properties are transformed into droplets traveling at velocities approaching a dozen meters per second. At IPI, the printhead track explores this core of inkjet technology – focusing on what productivity, durability, and performance truly mean for OEMs who need reliable uptime and predictable costs.

BEYOND RESOLUTION: THE TRUE MEANING OF PRODUCTIVITY

When we talk about productivity in printheads, the conversation often begins and ends with specifications: resolution, frequency, velocity. These are important, but they are not the whole story. For an OEM building a sustainable printing system, productivity is measured not in droplets per second, but in uptime, consistency, and predictability.

Aidan Feighan, Technical Special Projects Manager, Fujifilm Dimatix stresses this broader perspective. In a production environment, a printhead is valuable not just because it can jet faster. Its real value is in continuing to jet reliably after thousands of hours. Predictable performance minimizes downtime and simplifies cost modeling, allowing OEMs to promise end-users both speed and consistency. This is where productivity becomes less about “how fast can it go?” and more about “how long can it keep going at the same quality?” His perspective highlights why uptime and consistency often matter more to OEMs than sheer jetting speed.

12 November 2025, 11:20: “Performance, Productivity, Durability: Behind the Slogan, at the Core of Fujifilm Dimatix’ Inkjet Technology” by Aidan Feighan, Fujifilm Dimatix

Visitor takeaway: Productivity in printheads is defined by predictable performance and minimized downtime – the real drivers of cost efficiency on the factory floor.

DURABILITY VS. COST: THE LIFECYCLE EQUATION

Another central tension lies between durability and cost. At one end of the market, disposable printheads allow low entry cost and are suited to short-lifecycle applications. At the other, long-life printheads are expected to match or even outlast the machine they are integrated into.

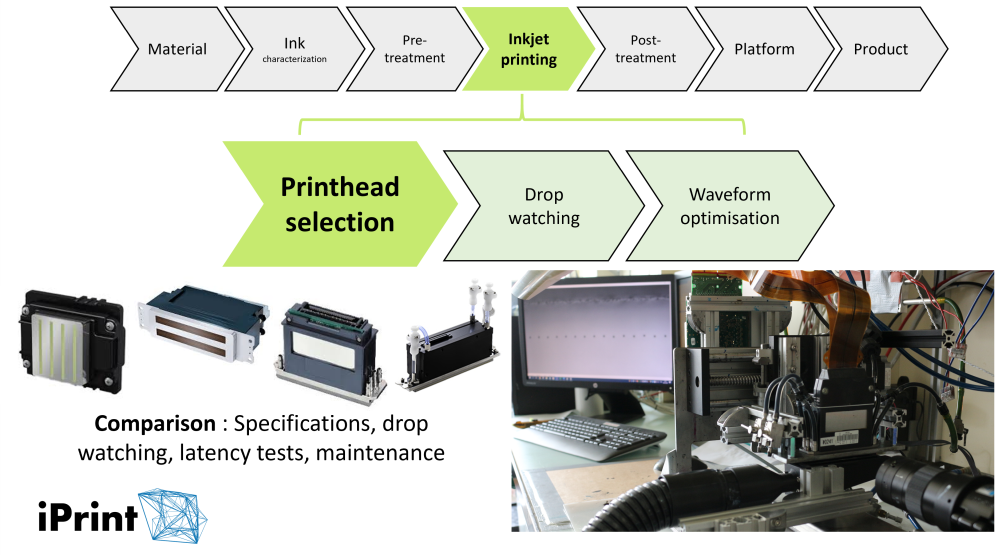

This is not a binary choice but a lifecycle equation: maintenance cycles, purging routines, and cleaning strategies all factor into real-world durability. Natalia Carrie, Senior Academic Associate UAS, Electrical Engineering at the iPrint Institute (Swiss inkjet and R&D center) illustrates this with comparative testing, where droplet behavior after idle times (latency tests), nozzle check patterns, and purging consumption provide data on the hidden cost of ownership. These metrics remind us that durability is not just about how long a printhead lasts, but how much it costs to keep it performing at specification. Her work shows OEMs how test data on latency and purging can reveal the hidden ownership costs of different printhead strategies.

Excerpt from Natalia Carrie’s presentation

Excerpt from Natalia Carrie’s presentation

12 November 2025, 15:20: “Printheads Comparison: How to Match the Requirements?” by Natalia Carrie, iPrint Institute

Visitor takeaway: Durability isn’t just about how long a printhead lasts, but how affordable it is to keep it performing over time.

EXPANDING THE TECHNICAL ENVELOPE

Printhead development is also being driven by expanding application requirements. Konica Minolta, for instance, has engineered a new 600 dpi head with dual-color capability and long-throw distance jetting – features that address very different market needs simultaneously. In décor applications, printing on non-flat surfaces requires both throw distance and stability, while packaging and label printing increasingly demand high-resolution multi-color capability. Konica Minolta’s dual-color, long-throw head demonstrates how one innovation can serve both décor and packaging markets, giving OEMs more flexibility.

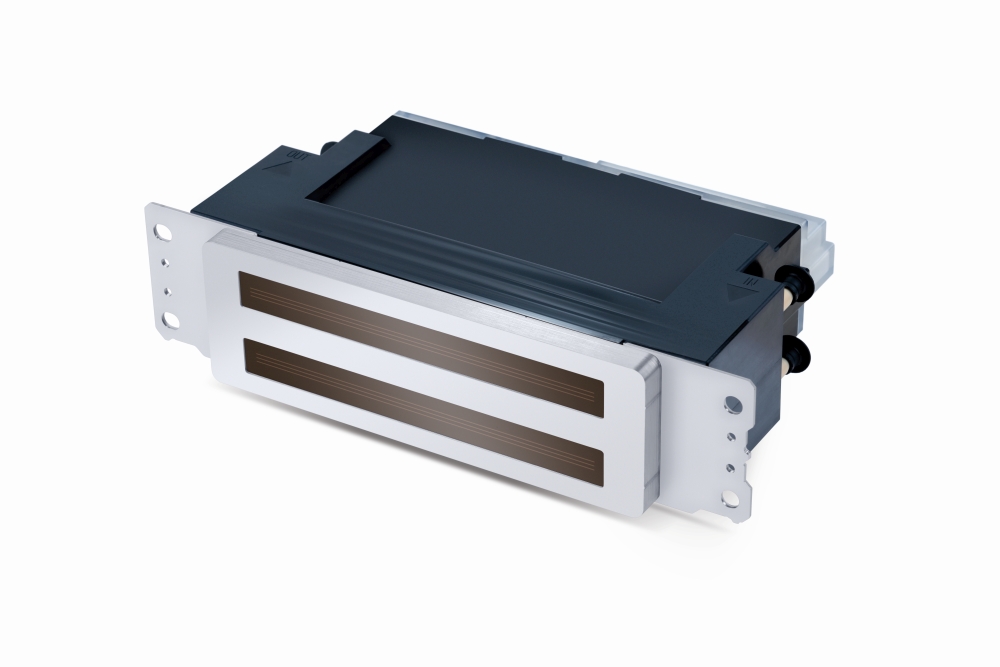

Konica Minolta’s KM1800iSHK-DC

Konica Minolta’s KM1800iSHK-DC

12 November 2025, 12:10: “Konica Minolta’s Newly Developed 600 dpi Printhead: Technical Perspective and Applications” by Kenji Mawatari, Konica Minolta

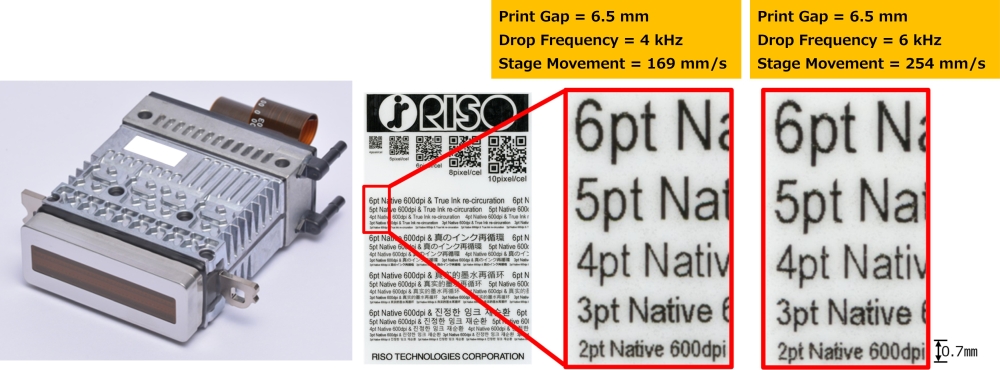

RISO Technologies, meanwhile, takes a different route, focusing on high-gap shear-mode jetting to reliably produce scannable QR codes even under challenging conditions. This speaks directly to the rise of packaging workflows where inkjet print units must be integrated into logistics and supply chain processes. RISO’s shear-mode jetting ensures reliable QR code printing, helping packaging workflows integrate smoothly with logistics and supply chains.

What connects these innovations is a rethinking of physical constraints: how far can a droplet fly and still land precisely? How small can it be while remaining stable? How do we maintain consistency across thousands of nozzles over months of use?

RISO Technologies’ CF6R printhead

RISO Technologies’ CF6R printhead

12 November 2025, 12:35: “RISO Technologies’ Approach to Achieving Quality High-Gap Printing and Integrated Packaging Workflow” by Dr Mengfei Wong, RISO Technologies

Visitor takeaway: As applications diversify, new printhead designs are expanding the technical envelope to meet real-world industry requirements.

CUSTOMER-DRIVEN INNOVATION

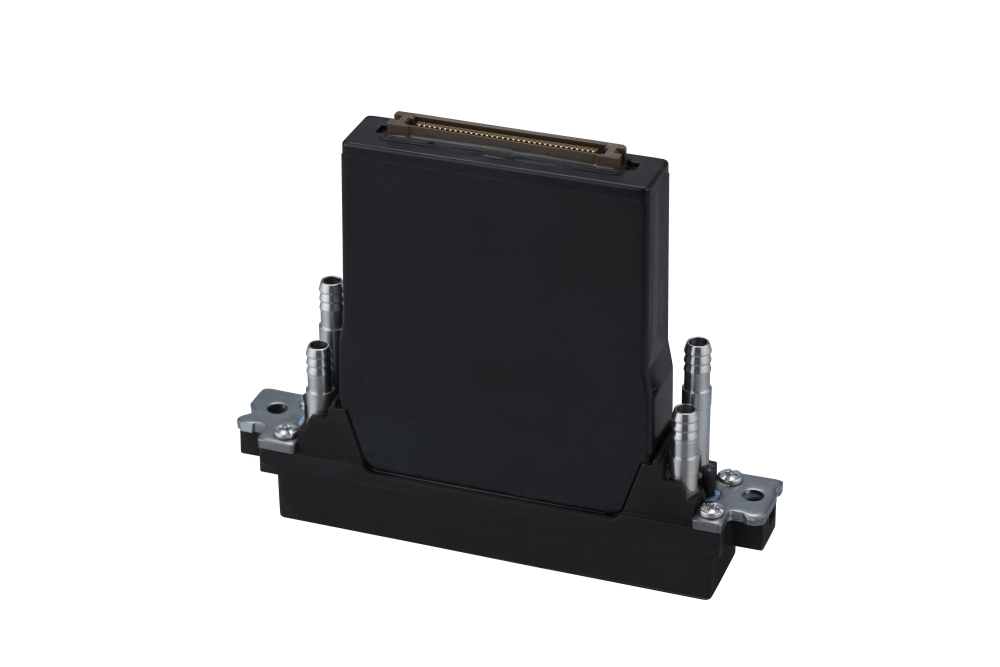

Perhaps the most telling trend is how directly customer requirements are shaping technical features. Fabio Tallarico of Seiko Instruments highlights this feedback loop: nozzle designs, fluid handling strategies, and lifetime improvements are developed not in isolation, but in response to specific customer challenges. The result is printheads optimized for reduced downtime, wider application coverage, and operational flexibility. His insight underscores how customer challenges directly shape nozzle design and fluid strategies, ensuring OEMs get solutions built for their markets.

This highlights an important shift: innovation is no longer about one-size-fits-all performance gains. Instead, it is about targeted improvements that align with OEM strategies, whether for textile printing, electronics manufacturing, or packaging.

Seiko’s RCE2560

Seiko’s RCE2560

12 November 2025, 11:45: “Your questions – our innovations: The Journey to a New Printhead” by Fabio Tallarico, Seiko Instruments

Visitor takeaway: Innovation is no longer one-size-fits-all – it’s customer-driven, with printheads increasingly tailored to specific industries like textiles, electronics, and packaging.

THE UNFINISHED STORY OF PRINTHEADS

Finally, Frederic Pimparel of Ricoh reminds us that inkjet printheads are far from a finished technology. The dream of a “universal printhead” – capable of handling every fluid, every application, every requirement – remains elusive. Physics resists. Markets diverge. Every solution comes with trade-offs.

But within those trade-offs lies opportunity. The unfinished story of printheads is one of specialization: new nozzle architectures, novel actuation mechanisms, and material innovations that keep pushing the boundaries of what can be jetted.

His reminder reinforces that the pursuit of a ‘universal printhead’ remains elusive, but the trade-offs create space for specialization and opportunity.

12 November 2025, 14:30: “The Unfinished Story of Inkjet Printheads – What Else Can We Explore?” by Frederic Pimparel, Ricoh

Visitor takeaway: The story of printheads is far from finished — specialization and new architectures continue to open opportunities for OEMs in diverse markets.

WHY PRINTHEADS STILL FILL THE ROOM

At IPI, the printhead track is never just about incremental improvements. It is about understanding the deeper mechanics of productivity and durability, and how these translate into competitive advantage for OEMs. Whether through comparative studies, long-life design philosophies, or high-gap shear-mode innovations, the message is clear: printheads remain the bottleneck and the enabler.

As inkjet extends into more industries – from décor and textiles to packaging and electronics – the demands on printheads will only multiply. Their story is not finished, and that is why the room is always full.

Visitor takeaway: Printheads remain the bottleneck and the enabler – making them one of the most valuable sessions to attend at IPI 2025.

See the complete IPI 2025 programme and plan your track.